-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Pricing

- Contact

Menu

X- home

-

Product >

-

Automated laser cutting, empowering you to effortlessly step into the era of smart manufacturing.

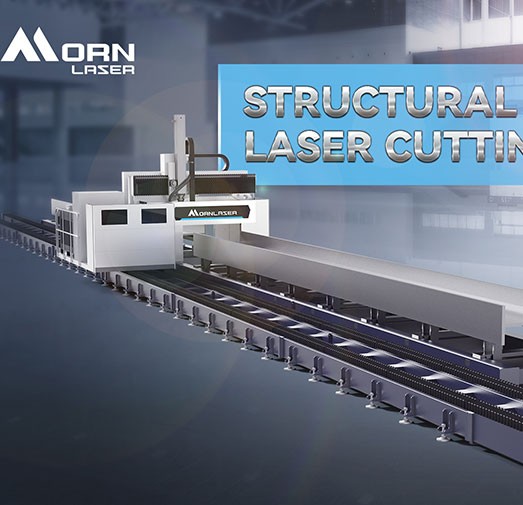

Fully Automatic Loading & Unloading Laser Cutting Production Line

1.5GMaximum acceleration140m/minMaximum linkage speed100mmMaximum SS cutting thickness60000wMaximum laser power![Fully Automatic Loading & Unloading Laser Cutting Production Line]() Benefits you can get from our laser cutting machine with storage tower

Benefits you can get from our laser cutting machine with storage tower![]() High-Level Automation

High-Level Automation![]() Labor Cost Reduction

Labor Cost Reduction![]() Space-saving

Space-saving![]() High Flexibility

High Flexibility![Video Thumbnail]()

![YouTube Logo]()

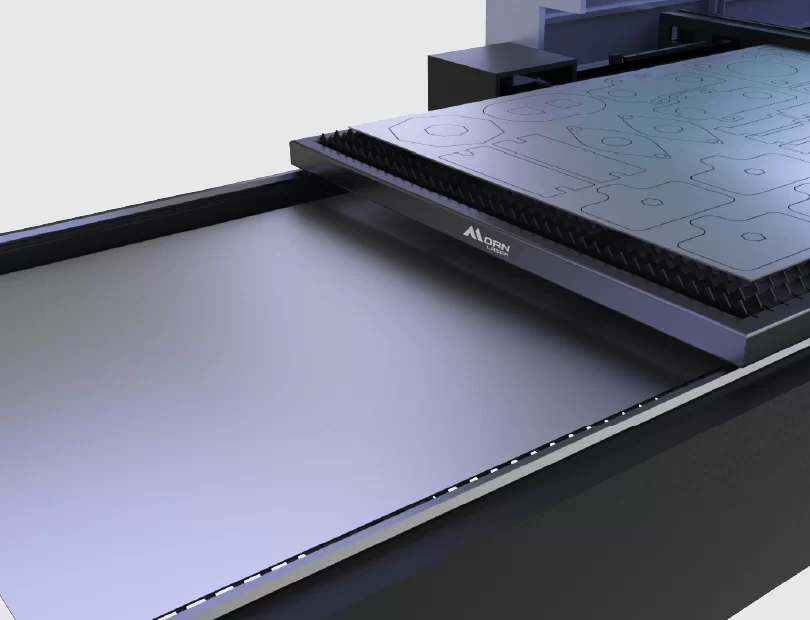

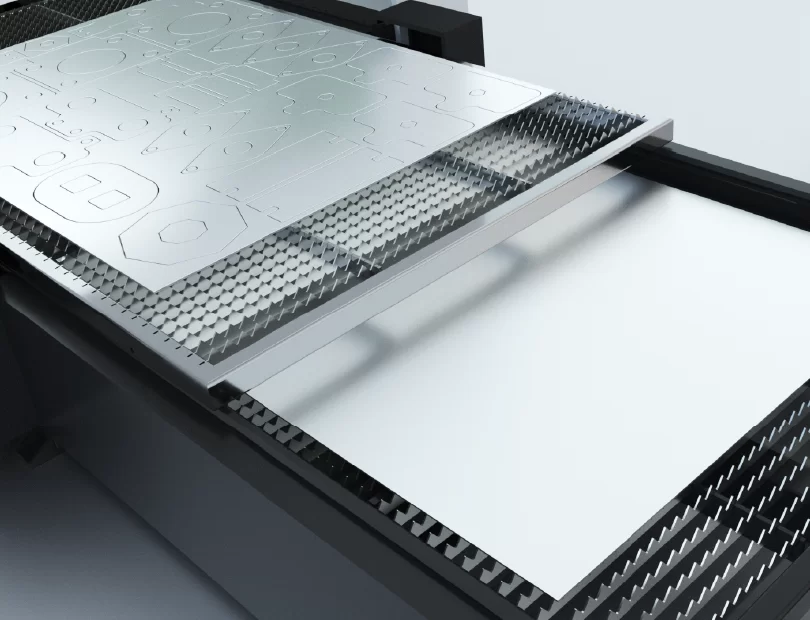

Auto up & down chain-type parallel pallets systemkeeps your production flowing without machinestop.With an immediate switch, you benefit fromthe fastest speed of pallet exchanging.

Customizable ultra large cutting format as large as 3100mm*14000mm.

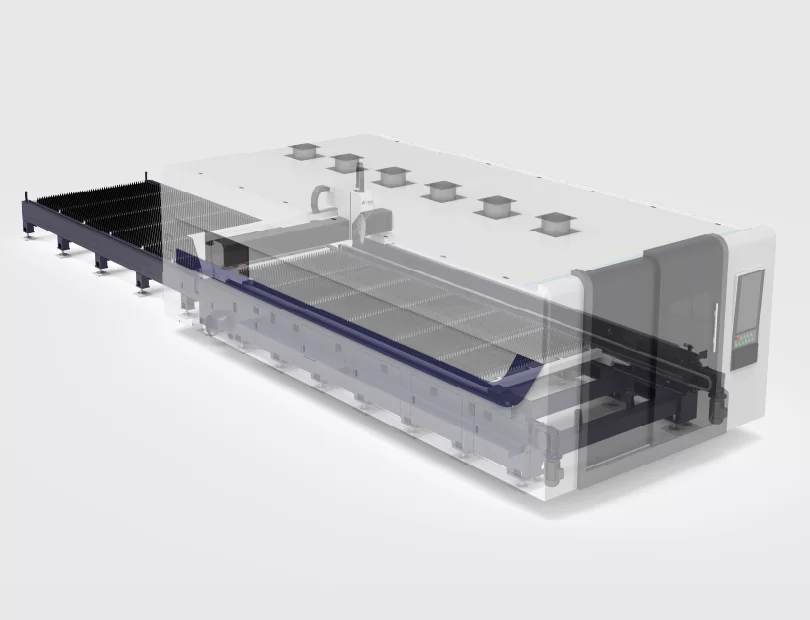

A fully enclosed structure with exclusive opticalfiber wavelength visible protection window anddust removal system that meet EU environmentstandards. Every detail promises a safe andpollution-free environment.

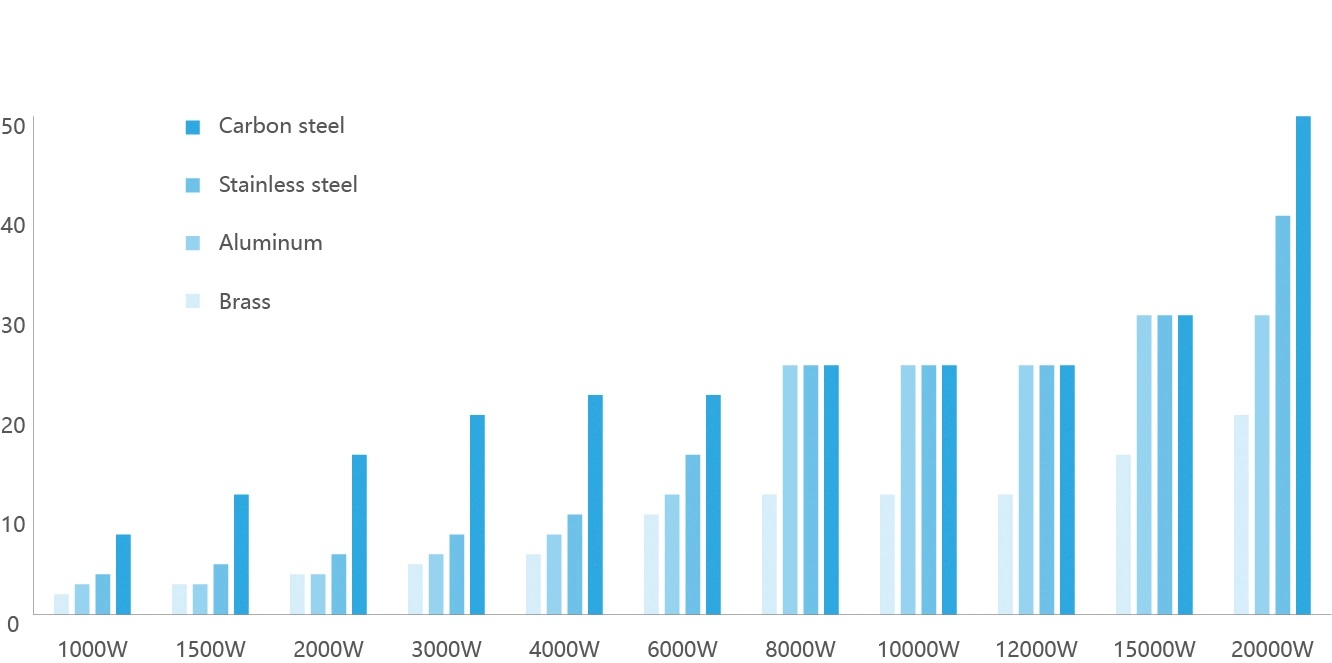

Double exchange platformUitra large cutting areaSafe productionTechnical Data Cutting ParametersModel MT-L1530FH MT-L2040FH MT-L2560FH MT-L20120FH MT-L25120FH Working Area (Customizable) 3000*1500mm 4000*2000mm 6000*2500mm 12000*2000mm 12000*2500mm Laser Power 2000W/3000W/4000W/6000W/12000W/20000W/30000W/40000W/60000W Repeat Positioning Accuracy ±0.02mm Maximum linkage speed 140m/min Maximum Acceleration Speed 1.5G Power Supply AC380V 50HZ AC220V 60HZ

You may also find these topics interesting

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

It can stably clamp round tubes, square tubes, I-beams, channel steels, special-shaped tubes, etc., to achieve efficient and stable cutting. It can be equipped with an automatic feeding system to achieve super-strong feeding and improve cutting efficiency.

This laser cutting machine is specially designed for the steel structure industry and is suitable for cutting I-beams, H-beams, channel steels and other profile steels. It can be accurately connected to Tekla, reducing manual drawing time and improving production efficiency;

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

It can stably clamp round tubes, square tubes, I-beams, channel steels, special-shaped tubes, etc., to achieve efficient and stable cutting. It can be equipped with an automatic feeding system to achieve super-strong feeding and improve cutting efficiency.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote x

Get a Quote

Get a Quote x

![]()